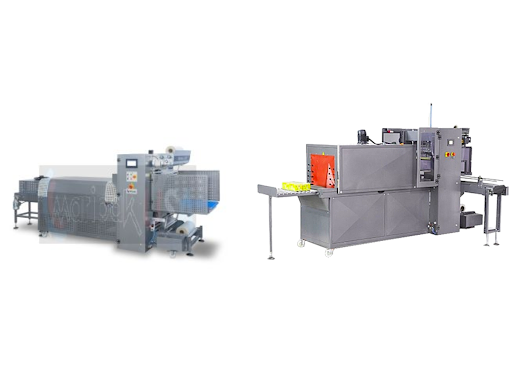

In modern production facilities, efficiency and presentation are key. From food to consumer goods, manufacturers rely on advanced packaging equipment to ensure products are well-protected and market-ready. Among these tools, the shrink packaging machine stands out as one of the most widely used due to its ability to provide a professional, tamper-evident seal. While these machines enhance productivity, they also come with specific safety considerations that operators must follow.

Operating a shrink system involves heat, moving parts, and electrical components. Without proper training and precautions, accidents can occur. For that reason, understanding key safety protocols not only safeguards employees but also extends the machine’s lifespan and prevents costly downtime.

Why Safety Matters in Shrink Packaging

The shrink process involves wrapping a product in plastic film and using heat to shrink the material tightly around the item. While seemingly simple, this procedure requires controlled exposure to high temperatures and mechanical handling. An improperly handled system can lead to risks such as burns, electrical shocks, or film mishaps. Safety is not just about compliance—it directly influences operational efficiency and product quality.

Key Safety Tips for Operators

Understand the Machine Before Use

Training is the first and most crucial safety step. Operators should be fully briefed on the specific model of the shrink packaging machine, including its control panel, temperature settings, film loading, and emergency shut-off functions. Regular training updates ensure that both new and experienced operators stay current on best practices.

Keep Work Areas Clear

Cluttered workstations are a major hazard. Loose film rolls, tools, or packaging debris near the sealing bar or conveyor can obstruct operation and create trip hazards. A clean, organized environment is essential to avoid accidents and improve workflow.

Protect Against Heat Hazards

The sealing bar and tunnel components operate at high temperatures, often exceeding 300°F. Operators must wear heat-resistant gloves when adjusting film, clearing jams, or conducting maintenance. Clear signage warning of hot surfaces should always be in place to prevent accidental contact.

Regularly Inspect Electrical Components

Since these machines require consistent electrical power, damaged cords, loose wiring, or improper grounding can present shock risks. Routine inspections ensure that the machine operates safely and minimizes downtime.

Never Bypass Safety Features

Modern shrink machines are equipped with built-in safety systems such as emergency stop buttons, safety interlocks, and automatic cool-down functions. These features should never be disabled for convenience. Ignoring them might save a few seconds in the short term but can lead to severe accidents in the long run.

Handle Film Properly

Film rolls are large, heavy, and sometimes sharp around the edges. Improper handling can cause strain or cuts. Using lifting aids, storing rolls securely, and following ergonomic practices protect operators from injuries.

Preventive Maintenance Is Essential

Routine maintenance reduces the chance of unexpected breakdowns. Tasks such as checking the sealing wires, inspecting conveyor belts, and cleaning tunnel fans should be scheduled regularly. A well-maintained machine not only improves safety but also extends the system’s operational life.

Proper Use of the Heat Shrink Tunnel Machine

In many production environments, a heat shrink tunnel machine is used in conjunction with a sealing system to provide consistent, high-speed packaging. While tunnels increase efficiency, they also present unique safety concerns:

- Avoid leaning over or reaching inside the tunnel during operation.

- Ensure adequate ventilation around the tunnel to prevent overheating.

- Regularly check that tunnel curtains are intact to contain heat effectively.

Following these precautions ensures operators can work efficiently without exposure to excessive heat.

Conclusion

The shrink packaging machine is an invaluable tool for businesses that want durable, tamper-resistant, and professional packaging. However, with its benefits comes the responsibility of proper handling. By following safety tips such as training operators, respecting heat zones, maintaining the heat shrink tunnel machine, and emphasizing preventive care, companies can protect workers and maximize productivity. Prioritizing safety ensures that packaging operations run smoothly, efficiently, and without unnecessary risks—making it clear that in packaging, safety is always the smartest investment.